Glass Tooling Hut – Engineered for precision, built for the demands of modern glass processing.

Key Features

- Specially designed to organize, store, and protect glass tools used in cutting, edging, polishing, or installation.

- Lined or coated surfaces to prevent scratches or damage to delicate glass tools and accessories.

- Dedicated slots, hangers, and shelves for every type of glass tool—from cutters to polishing pads.

- Built-in lighting ensures clear visibility for tool selection and maintenance.

- Power up small electric glass tools directly within the hut for a complete workstation setup.

What is a Glass Tooling Hut?

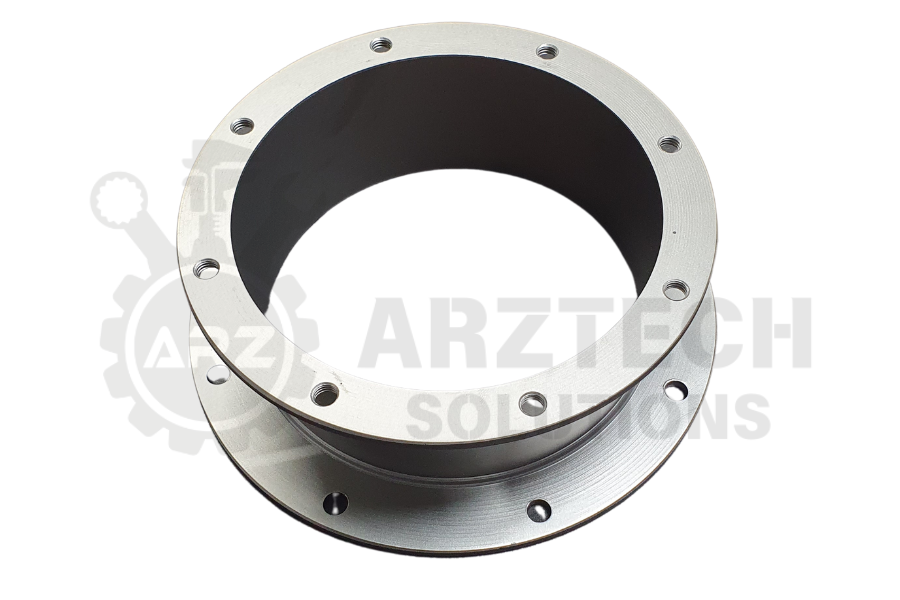

A Glass Tooling Hut is a specialized enclosed unit within a glass processing machine that houses cutting, drilling, grinding, and polishing tools. It provides a controlled environment for precision glass machining, ensuring high accuracy while minimizing dust, debris, and tool wear. These units are commonly integrated into CNC glass machines, drilling systems, and edge-finishing equipment for automotive, architectural, and industrial glass processing.

Key Features:

- Enclosed tooling area for safety and precision

- Supports multiple tool types (cutters, drills, grinders)

- Integrated cooling & lubrication system for extended tool life

- Compatible with CNC & automated machines

- Dust & debris control for a cleaner work environment

Uses of Glass Tooling Hut

- Glass Cutting & Shaping: Used in CNC machines for precise cutting of glass sheets.

- Glass Drilling: Ensures high-precision hole drilling for windows, display panels, and shower doors.

- Edge Grinding & Polishing: Helps smooth and refine glass edges for a clean finish.

- Beveling & Chamfering: Essential for decorative and architectural glass applications.

- Tempered & Laminated Glass Processing: Prepares glass before heat treatment for added strength.

- Electronics & Display Manufacturing: Used for smartphone screens, tablets, and LED displays.

- Automotive & Aerospace Glass Fabrication: Assists in creating curved and laminated windshields.

Additional Information

Technical Specifications:

- Material: High-strength steel & industrial-grade composites.

- Tool Compatibility: Diamond drills, grinding wheels, polishing heads.

- Cooling System: Integrated water/air cooling mechanism.

- Automation Support: Works with most CNC glass machines.

- Customization: Available for specific glass processing needs.

Advantages of Using a Glass Tooling Hut:

- Enhanced Accuracy – Ensures precise drilling, cutting, and polishing

- Increased Tool Life – Reduces wear on cutting and grinding tools

- Reduced Downtime – Optimized workflow with automated tool handling

- Cleaner Work Environment – Minimizes glass dust and debris

- Seamless Machine Integration – Easily fits into existing glass processing setups